Vision-based autonomous structural damage detection using data-driven methods

Summary

Paper digest

What problem does the paper attempt to solve? Is this a new problem?

The paper addresses the problem of automated damage detection in wind turbine structures using advanced deep learning algorithms. This issue is critical due to the various environmental and operational stresses that wind turbines face, such as erosion, cracks, and dirt accumulation, which can significantly affect their performance and lifespan .

While damage detection in structural health monitoring (SHM) is not a new problem, the paper emphasizes the need for improved methodologies that leverage vision-based systems to enhance efficiency and accuracy compared to traditional manual inspection methods, which are often labor-intensive and pose safety risks . The integration of deep learning techniques, particularly the YOLOv7 algorithm, represents a significant advancement in addressing this ongoing challenge, making it a relevant and contemporary issue in the field of SHM .

What scientific hypothesis does this paper seek to validate?

The paper seeks to validate the hypothesis that automated systems utilizing image-based deep learning methods can effectively detect and localize surface damage in wind turbine structures. Specifically, it aims to evaluate the performance of three deep learning algorithms—YOLOv7, tiny YOLOv7, and Faster R-CNN—in detecting and classifying various types of surface damage, such as cracks, erosion, and dirt . By addressing this hypothesis, the research contributes to advancements in structural health monitoring (SHM) practices and demonstrates the potential of vision-based systems in enhancing safety and reducing maintenance costs .

What new ideas, methods, or models does the paper propose? What are the characteristics and advantages compared to previous methods?

The paper presents several innovative ideas, methods, and models aimed at enhancing structural health monitoring (SHM) practices, particularly in the context of wind turbine inspections. Below is a detailed analysis of these contributions:

1. Advanced Deep Learning Models

The study evaluates three deep learning architectures: YOLOv7, YOLOv7-Tiny, and Faster R-CNN.

- YOLOv7 is highlighted for its real-time performance and high accuracy, making it suitable for on-site inspections .

- YOLOv7-Tiny is a lightweight variant optimized for edge devices, which sacrifices some accuracy for enhanced speed, making it ideal for environments with limited computational resources .

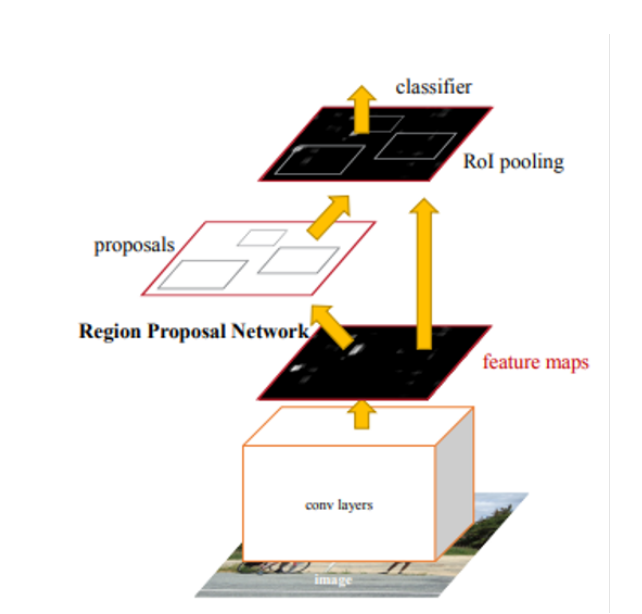

- Faster R-CNN is noted for its effectiveness in detecting low-contrast damages, although it is computationally intensive and slower compared to YOLO models .

2. Data Augmentation Techniques

To improve model generalization and mitigate overfitting, the paper employs various data augmentation techniques such as rotation, scaling, flipping, and brightness adjustments. These methods enhance the models' robustness against diverse real-world scenarios .

3. Hybrid Model Architectures

The authors propose the development of hybrid architectures that combine the strengths of YOLOv7 and Faster R-CNN. This integration aims to optimize both accuracy and speed, addressing the limitations of individual models .

4. Dataset Expansion

The paper emphasizes the need for expanding datasets to include a wider variety of damage types and environmental conditions. This expansion is crucial for improving model robustness and adaptability, particularly in real-world applications .

5. Incorporation of Segmentation Algorithms

Future research directions include exploring the use of segmentation algorithms such as Mask R-CNN or U-Net. These models could provide more detailed insights into the extent and severity of damages, enhancing the functionality of SHM systems .

6. Real-Time Applications and Edge Computing

The study highlights the potential for deploying YOLOv7-Tiny in real-time applications and edge computing scenarios. This capability is particularly valuable for inspections in remote or resource-constrained environments, aligning with the growing demand for portable and efficient SHM solutions .

7. Performance Evaluation and Comparative Analysis

The paper includes a comprehensive performance comparison of the models, showcasing YOLOv7's superior balance of accuracy and speed, while also detailing the strengths and weaknesses of each model in various contexts .

8. Broader Implications for SHM Practices

The findings underscore the transformative potential of vision-based deep learning models in SHM, suggesting that automated damage detection can significantly reduce inspection costs, enhance safety, and improve operational efficiency .

In summary, the paper proposes a multifaceted approach to advancing SHM practices through the integration of advanced deep learning models, innovative data handling techniques, and a focus on real-time applications, all aimed at improving the efficiency and reliability of structural damage detection. The paper outlines several characteristics and advantages of the proposed vision-based autonomous structural damage detection methods, particularly focusing on the YOLOv7, YOLOv7-Tiny, and Faster R-CNN models. Below is a detailed analysis comparing these methods to previous approaches in structural health monitoring (SHM).

1. Advanced Deep Learning Architectures

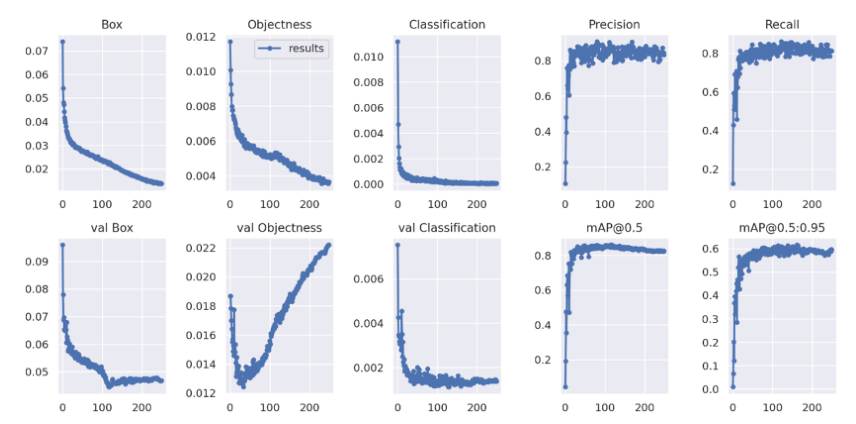

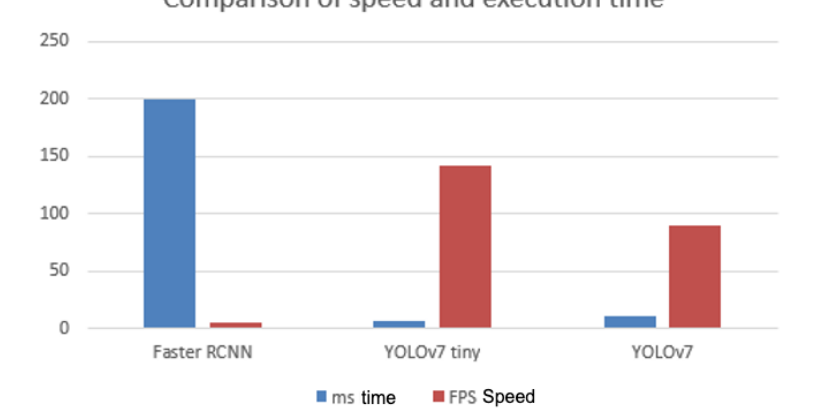

- YOLOv7 is a one-stage object detection model known for its real-time performance and high accuracy. It achieves an mAP@50 of 82.4% and an execution time of 11 ms per image, making it suitable for real-time applications .

- YOLOv7-Tiny, a lightweight variant, is optimized for edge devices, achieving an execution time of 7 ms per image. While it sacrifices some accuracy (mAP@50 = 79.8%), it is ideal for environments with limited computational resources .

- Faster R-CNN, while effective in detecting low-contrast damages, has slower execution times (200 ms per image) and is more computationally intensive, making it less suitable for real-time applications .

2. Enhanced Detection Capabilities

- The YOLO models excel in detecting general damage types, while Faster R-CNN is more effective for low-contrast and small damages. This specialization allows for a broader range of applications in SHM, addressing limitations seen in traditional methods that often rely on manual inspections or non-destructive testing (NDT) .

- The use of data augmentation techniques (rotation, scaling, brightness adjustments) enhances model generalization and robustness, which is crucial for handling diverse real-world scenarios .

3. Automation and Efficiency

- The adoption of these deep learning models marks a significant advancement in automated inspection methodologies. Traditional methods are often labor-intensive and time-consuming, whereas vision-based systems provide rapid, accurate, and non-contact solutions, thereby reducing maintenance costs and enhancing safety .

- The ability to perform real-time inspections using YOLOv7 and YOLOv7-Tiny allows for immediate damage detection, which is particularly valuable for offshore wind turbines where accessibility is limited .

4. Dataset Quality and Diversity

- The study emphasizes the importance of a comprehensive dataset derived from publicly available sources, comprising 2,995 labeled images of wind turbine surfaces. This dataset includes various damage types and conditions, which is critical for training robust models .

- The quality and diversity of the dataset significantly impact model performance, aligning with findings from previous studies that highlight the need for diverse datasets to enhance deep learning model robustness .

5. Hyperparameter Optimization

- The paper details the optimization of key hyperparameters (learning rate, batch size) for each model, which contributes to improved detection accuracy and speed. This systematic approach to model training is a notable advancement over previous methods that may not have employed such rigorous optimization techniques .

6. Broader Implications for SHM Practices

- The findings underscore the transformative potential of vision-based deep learning models in SHM, suggesting that automated damage detection can significantly reduce inspection costs, enhance safety, and improve operational efficiency. This contrasts with traditional methods that often lack the scalability and efficiency of modern algorithms .

Conclusion

In summary, the characteristics and advantages of the proposed methods over previous approaches include advanced deep learning architectures with real-time capabilities, enhanced detection of various damage types, automation that reduces labor costs, and the utilization of high-quality datasets. These advancements collectively contribute to more efficient, reliable, and scalable solutions in structural health monitoring, particularly in the context of wind turbine inspections.

Do any related researches exist? Who are the noteworthy researchers on this topic in this field?What is the key to the solution mentioned in the paper?

Related Researches and Noteworthy Researchers

Numerous studies have contributed to the field of structural health monitoring (SHM) using advanced deep learning techniques. Noteworthy researchers include:

- K. Zhou, C. Fu, and S. Yang: Their work on big data-driven smart energy management highlights the integration of data analytics in energy systems .

- S. Dorafshan et al.: They have conducted significant research on fatigue crack detection using unmanned aerial systems, emphasizing the application of deep learning in infrastructure inspections .

- Y. J. Cha et al.: Their study on autonomous structural visual inspection using deep learning has been pivotal in advancing automated damage detection methodologies .

Key to the Solution

The key to the solution mentioned in the paper lies in the adoption of YOLOv7 and its variants for automated damage detection in wind turbine structures. This approach marks a significant advancement over traditional inspection methods by providing rapid, accurate, and non-contact solutions, thereby reducing maintenance costs and enhancing safety . The study emphasizes the importance of dataset quality and hyperparameter optimization in achieving superior performance, which is crucial for real-time applications in SHM .

How were the experiments in the paper designed?

The experiments in the paper were designed with a focus on evaluating the performance of three deep learning models—YOLOv7, YOLOv7-Tiny, and Faster R-CNN—for automated damage detection in wind turbine structures. Here are the key components of the experimental design:

Dataset Preparation

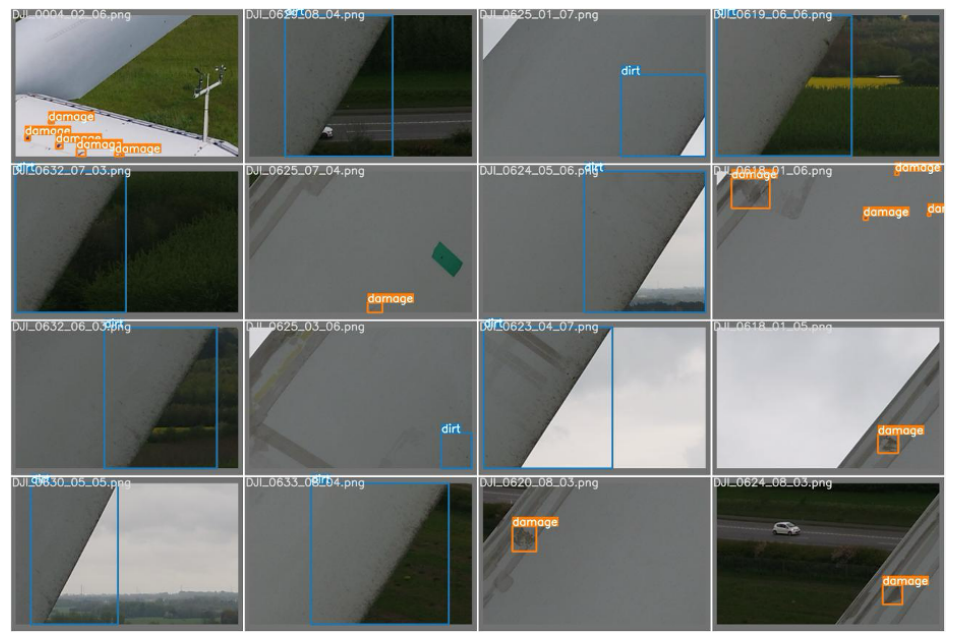

- The dataset consisted of 2,995 labeled images of wind turbine surfaces, categorized into damage and pollution types. These images were sourced from publicly available datasets, including the Nordtank wind turbine dataset and DTU drone inspection images .

- The dataset was split into three subsets: 80% for training (2,396 images), 10% for testing (299 images), and 10% for evaluation (300 images) .

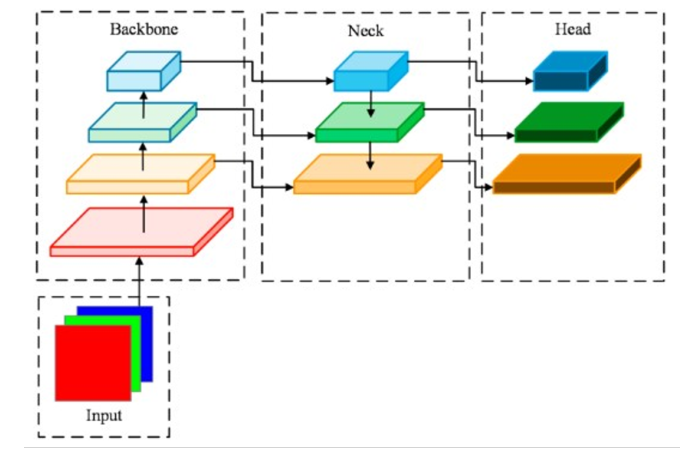

Model Architectures

- Three models were evaluated: YOLOv7, YOLOv7-Tiny, and Faster R-CNN. Each model's architecture was designed to optimize performance for specific tasks, with YOLOv7 being a one-stage detector known for real-time performance, while Faster R-CNN is a two-stage detector effective for detailed object detection .

Training Procedures

- Hyperparameter optimization was conducted for each model, adjusting settings such as learning rate, batch size, and momentum to enhance performance. For instance, YOLOv7 used a learning rate of 0.01 and a batch size of 16 .

- Data augmentation techniques, including rotation, scaling, and brightness adjustments, were employed to improve model generalization and mitigate overfitting .

Evaluation Metrics

- The models were evaluated using several metrics: Mean Average Precision (mAP), precision, recall, and execution time. These metrics provided a comprehensive assessment of each model's performance in detecting and localizing surface damage .

Results Analysis

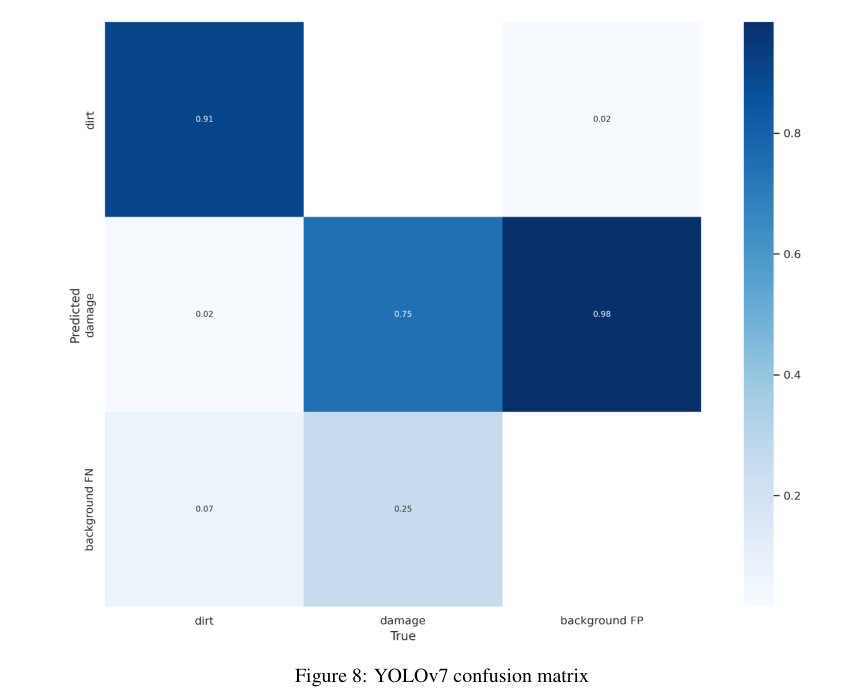

- The results were analyzed to compare the models' performance in terms of accuracy and speed, with YOLOv7 demonstrating the highest mAP and execution speed, making it suitable for real-time applications .

This structured approach allowed for a thorough evaluation of the models' capabilities in the context of structural health monitoring (SHM) for wind turbines.

What is the dataset used for quantitative evaluation? Is the code open source?

The dataset used for quantitative evaluation in this study is the Nordtank wind turbine dataset, which comprises 2,995 labeled images of wind turbine surfaces categorized into damage and pollution types . The dataset was derived from publicly available sources, including DTU drone inspection images, and was split into training, testing, and evaluation subsets to ensure effective model assessment .

Regarding the code, the context does not specify whether it is open source. Therefore, additional information would be required to determine the availability of the code.

Do the experiments and results in the paper provide good support for the scientific hypotheses that need to be verified? Please analyze.

The experiments and results presented in the paper provide substantial support for the scientific hypotheses regarding the efficacy of advanced deep learning algorithms for structural health monitoring (SHM).

Model Performance Evaluation

The study evaluates three models—YOLOv7, YOLOv7-Tiny, and Faster R-CNN—using metrics such as mean Average Precision (mAP), precision, recall, and execution time. YOLOv7 achieved an mAP@50 of 82.4%, demonstrating its suitability for real-time applications due to its high accuracy and speed, with an execution time of 11 ms per image . This performance aligns with previous studies that emphasize the advantages of YOLO-based models in real-time detection scenarios .

Comparative Analysis

The results indicate that while YOLOv7 excels in speed and accuracy, Faster R-CNN is more effective in detecting low-contrast damages, albeit at slower speeds . This comparative analysis supports the hypothesis that different models have unique strengths and weaknesses, which is crucial for selecting appropriate algorithms based on specific application requirements .

Dataset Quality and Augmentation

The paper highlights the importance of dataset quality, noting that the Nordtank dataset, comprising 2,995 labeled images, was instrumental in achieving robust model training . The use of data augmentation techniques further improved model generalization, reinforcing the hypothesis that diverse datasets enhance model robustness .

Broader Implications

The findings underscore the transformative potential of vision-based systems in SHM, suggesting that automated damage detection can reduce inspection costs and enhance safety . This aligns with the hypothesis that integrating deep learning techniques can significantly advance SHM practices.

In conclusion, the experiments and results in the paper effectively support the scientific hypotheses regarding the capabilities of deep learning models in SHM, demonstrating their potential to improve accuracy, speed, and operational efficiency in damage detection tasks .

What are the contributions of this paper?

The contributions of the paper on vision-based autonomous structural damage detection using data-driven methods are as follows:

1. Development of Automated Systems

The primary objective is to create an automated system for detecting and localizing surface damage in wind turbine structures using image-based deep learning methods. This includes evaluating the performance of three deep learning algorithms—YOLOv7, tiny YOLOv7, and Faster R-CNN—in detecting and classifying surface damage .

2. Comprehensive Dataset Creation

The research aims to establish a comprehensive dataset of labeled images depicting various damage types, such as cracks, erosion, and dirt, to facilitate supervised learning. This dataset is crucial for training and validating the deep learning models .

3. Performance Comparison

The study compares the developed system with existing studies to assess its effectiveness and highlight advancements achieved through modern algorithms. YOLOv7 is noted for its superior performance in terms of accuracy and speed, making it a viable solution for real-time damage detection .

4. Optimization of Hyperparameters

The research emphasizes the importance of optimizing hyperparameters of the deep learning models to improve detection accuracy and speed, which is essential for practical applications in structural health monitoring (SHM) .

5. Advancements in SHM Practices

The findings contribute to the advancement of SHM practices by demonstrating the potential of vision-based systems to reduce maintenance costs, enhance safety, and ensure the reliability of wind turbines. This aligns with the broader implications of integrating deep learning techniques into SHM systems .

6. Future Research Directions

The paper outlines future research directions, including the expansion of datasets, exploration of hybrid model architectures, and incorporation of segmentation algorithms to provide detailed insights into damage extent and severity .

These contributions collectively advance the state-of-the-art in automated damage detection and highlight the transformative potential of deep learning in structural health monitoring.

What work can be continued in depth?

Future research directions in the field of structural health monitoring (SHM) can focus on several key areas:

1. Dataset Expansion

Expanding datasets to include a wider variety of damage types and environmental conditions is crucial. This includes integrating drone-captured images to enhance dataset diversity and representativeness, which can improve model robustness .

2. Hybrid Model Architectures

Combining the strengths of YOLOv7 with Faster R-CNN could lead to a hybrid model that balances real-time performance with detailed damage detection. This approach aims to optimize both accuracy and speed, addressing the limitations of individual models .

3. Incorporation of Segmentation Algorithms

Exploring the use of segmentation models, such as Mask R-CNN or U-Net, can provide more detailed insights into the extent and severity of damage. This could enhance the functionality of SHM systems by allowing for more precise localization of damage .

4. Deployment on Edge Devices

Optimizing models like YOLOv7-Tiny for deployment on edge devices can facilitate real-time inspections in resource-constrained environments. This aligns with the growing demand for portable and efficient SHM solutions .

5. Addressing Computational Requirements

Research should also focus on reducing the computational intensity of training processes, making advanced models more accessible for use in resource-limited settings .

By pursuing these avenues, future studies can significantly advance SHM practices and contribute to the sustainable maintenance of critical infrastructures .